Architect Kathleen Lechleiter ’81, ’82 is shaping safe, stable, and dignified housing in Baltimore neighborhoods.

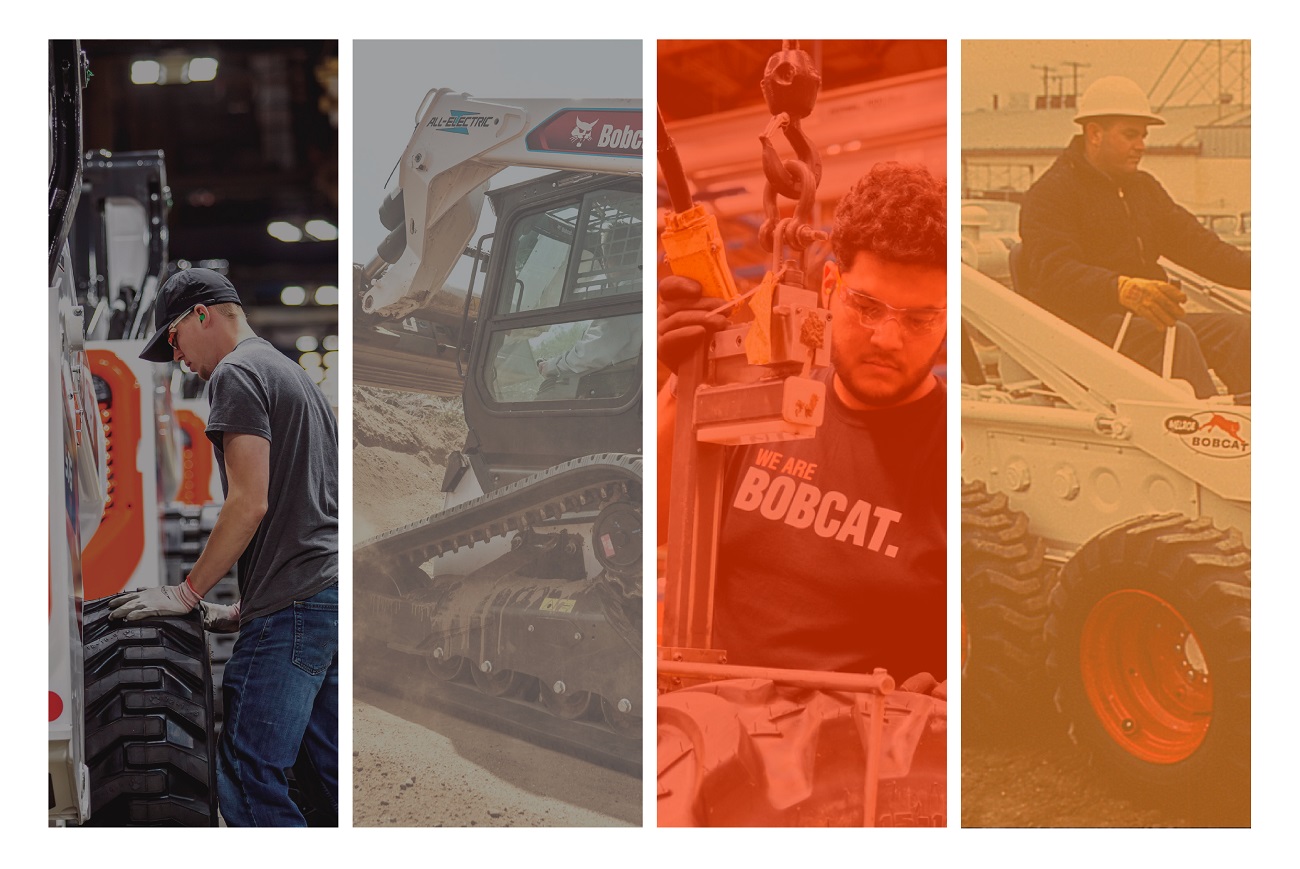

Read MoreInnovation Across Generations: The Doosan Bobcat Story

Doosan Bobcat's $4.5 million investment in STEM scholarships at NDSU is shaping the next generation of industry leaders.

Story by Drew Taylor '15, '25 | Photos by Doosan Bobcat | August 28, 2023

Since its founding in 1947, Bobcat has been driving innovation and advancement in many industries. Its roots in compact machinery stretch back to the late 1950s with the Keller brothers’ original concept for a lightweight, belt-driven loader designed to operate in a turkey farmer’s barn in Rothsay, Minnesota. After some retooling towards a clutch-based transmission, in 1962 the first compact loader was launched under the Bobcat name in honor of the agile and industrious prairie animal. Forty-five years later, in 2007, Bobcat joined the South Korean Doosan Group. It continues to expand its catalog of compact equipment, attachments, grounds maintenance, and construction-related products and services.

As Doosan Bobcat continues to innovate for the future, it sees immense potential in the bright, young minds of NDSU students. In 2015, the company invested $3 million to fund scholarships for students in STEM-related fields at NDSU. The gift was matched by the North Dakota Higher Education Challenge Grant Fund for an additional $1.5 million, and today the endowment disburses roughly $186,000 annually in scholarships. At the time of its establishment, the commitment was one of the largest gifts received by NDSU from a corporate partner.

“Our company’s foundation is built on innovation and the ingenuity of our people, many of whom are NDSU graduates, so supporting the NDSU STEM scholarships is a priority for us,” Joel Honeyman ’93, ’96, vice president of global innovation at Doosan Bobcat, said. “We value our relationship with NDSU and want to provide educational opportunities to teach and inspire students to thrive in an ever-evolving world.”

Joel Honeyman sees investing in STEM in North Dakota as a natural part of creating a thriving workforce.

“As a North Dakota-based company with so many employees with strong local roots, we value our relationship with NDSU and remain committed to nurturing the state’s and region’s future innovators, engineers, and technology leaders,” he said. “Whether STEM graduates end up working at Bobcat or other organizations in the region, having technology and engineering talent in our communities is a benefit to all of us.”

One of those North Dakota communities, Gwinner, holds a special place in Bobcat lore as its first headquarters. It’s also the hometown of Drew Asche ’21, a third-generation NDSU alumnus and Bobcat engineer.

“My grandpa worked at Bobcat as an engineer. My dad did as well. Now I do, too,” Drew said. “From a family standpoint, it’s always been an interest to me to work at Bobcat, and it’s also been a source of pride that this world-renowned product comes from your little hometown.”

Drew, now an engineer in the global hydraulics group at the Doosan Bobcat Acceleration Center in Bismarck, North Dakota, was a recipient of the Doosan Bobcat STEM scholarship. He got his first hands-on chance working at the company during a summer internship, which was quickly followed by a co-op, where he helped design an excavator. A co-op, or cooperative education, provides students with academic credit for structured job experience. Drew’s co-op experience paved the way for him to get hired a full semester before he graduated, and he took the opportunity to work part time while he finished his coursework.

Doosan Bobcat’s internship programs are as diverse and rigorous as the array of machinery it manufactures. The company actively recruits the next generation of pioneers and trailblazers by offering a range of programs tailored to meet the needs of students at different stages in their education. Doosan Bobcat’s co-op program allows college students to dive into real-world projects. Students from a variety of disciplines can additionally work part time during the school year and full time over the summer, gaining invaluable hands-on experience.

Doosan Bobcat also offers the Engineering Prototype Intern Program to freshman or sophomore students who are pursuing technical or engineering degrees. This program allows students to focus on shop work and offers design, test, or electrical-focused projects.

Paighe Wetzstein ’23, who graduated this past spring with a bachelor’s degree in statistics, also received the Doosan Bobcat scholarship, which motivated her to apply for a co-op position. She began her co-op during her sophomore year and continued all the way until her graduation, all the while attending NDSU full time.

Because she obtained different skills in her co-op and in the classroom at NDSU, Paighe found the experience to be central to her career.

“When I first got this co-op, I thought, ‘All of this has nothing to do with what I’m seeking.’ But, looking back, my advice would be: get an internship, get a co-op,” Paighe said. “It does not matter where it is, because even though this was not what I originally thought I was going to be doing, I love it, and now I have a whole career ahead of me.”

Co-ops and internships often lead to full-time employment, as Joel Honeyman notes.

“The co-op program that exists between Bobcat and NDSU allows students to work at Bobcat, putting learning into practice to contribute to real projects. As NDSU graduates are among the best and brightest, we hire many of its students to become part of our team — and I believe our people are some of the most qualified and innovative in the industry.”

Paighe’s case was a little different from that of most students. During her co-op, she worked as a strategy analyst with a multitude of responsibilities, but unlike most co-ops that simply transition into a full-time position with expanded duties, Doosan Bobcat recognized the importance of her work in setting internal goals on how the company can reduce its impact on the environment. Consequently, the company created a position specifically for her to collaborate with facilities across its footprint to exercise environmental social governance (ESG). For Paighe, this is a core value of the company.

“In order for us to be successful, we have to keep innovating and coming up with things that are relevant to the community, that will impact our community in a better way,” Paighe said.

Joel Johnson ’22 is one of those innovators of sustainable and safety-first solutions. He worked at Doosan Bobcat for over a year and a half as a co-op and intern before graduating into a full-time position there.

“Bobcat gave me the opportunity to develop my skills as an engineer while I was in school, and I got paid to do it. Plus, the things that I learned at Bobcat were often complementary to what I was learning at school,” he said. “For example, when I was taking computer architecture, I was also looking at some assembly code at Bobcat, so my understanding of the concepts that I was learning in class accelerated.”

While this type of synergy is common in co-ops and internships, Joel Johnson notes another interesting synergy in the work he’s been doing in the six months since he graduated: developing radar-sensing technology for the Doosan Bobcat lineup.

“We want to add visibility for the operators of our machines. One way to do that is by adding tailgate radars that would be able to sense things that the operator would normally have very limited visual awareness of, which could potentially prevent an accident. But the more visibility we add to the operator, the closer we get to having the ability to create autonomous vehicles. We’re adding visibility not only to our operator, but also to the computer inside the machine. We’re moving closer to having machine vision where the machine is able to see for itself and make decisions for itself.”

In addition to the co-op and internship programs that Joel Johnson, Paighe, and Drew have taken advantage of, Doosan Bobcat offers the unique Student Development Program that specifically targets NDSU engineering students who have previously held a co-op position at Bobcat. This program, which operates part time during the school year, allows students to work on more complex projects compared to the co-op program, providing a deeper understanding of the industry. Co-op students and interns can also participate in the Bobcat Bootcamp, which provides firsthand experience with Bobcat products and a unique perspective that transcends a traditional classroom setting.

These programs, in tandem with the Doosan Bobcat scholarship for NDSU STEM students, are part of a multifaceted effort by Bobcat to build a strong working relationship with NDSU and its students, Joel Honeyman states.

“Like other manufacturers and employers in the state, recruiting, growing, and retaining a quality, skilled workforce is an ongoing challenge. For Bobcat and other regional companies to remain competitive, we need the best and brightest engineers working across our sites.”

Private-public partnerships, like those between Doosan Bobcat and NDSU, have a profound impact on students’ education and careers. The relationship between Doosan Bobcat and NDSU is a testament to the power of collaboration between industry and the University, shaping the future for both students and businesses, and it all begins with scholarship support.

“I see a scholarship as an investment into someone or something, and with any investment, like in the business world, you really want that investment to grow. You don’t want it to depreciate,” Drew said. “When I view it as an investment, it makes me want to work harder to show my investors that their money is being put to good use and growing in value.”

Share This Story

Related Stories

Structures of Connection

Joanna Slominski ’04 wants us to think differently about construction — it’s more than bricks and concrete.

Read More