At NDSU, Alyssa Hodges ’21, ’23, ’26 discovered a community ready to support her in ways she hadn’t expected.

Read MoreThe Joy Is Invention

Lokesh Narayanan, Vettel Family Fellow, is making bold scientific advancements with one major goal in mind: improving the quality of human life.

Story by Micaela Gerhardt | Illustration by Leah Ecklund | September 28, 2021

In 1997, a photograph emerged of one extraordinary mouse sitting inside a petri dish on a white laboratory table. Like most mice, it had four legs, one tail, and two eyes; unlike most mice, it had three ears.

What caught people so off guard was not necessarily that the Vacanti mouse had three ears, but that it’s third ear, which grew on its back, looked exactly like a human ear. In fact, a team of medical researchers had constructed it this way. In an effort to contend with organ shortages for human patients, the researchers were studying the mouse and evaluating the potential for producing tissue-engineered organ replacements for people.

After a BBC News program highlighted the research, the photograph circulated rapidly, generating widespread recognition that making and molding tissues in a laboratory was possible; however, it stirred controversy among people who viewed animal testing or genetic engineering as unethical. In an interview with Newsweek in 2017, head researcher Joseph Vacanti reflected on some of the ethical debates surrounding his past experiment.

“In the world of medicine, there’s a massive controversy about the use of animals,” he said. “We’re hoping to eliminate the need to use animals because we can now generate human structures and tissues using human cells, and we can study them without the use of animals. That’s our long-term goal.”

"The joy, to me, is invention. I know it's a bit outlandish, but I want to improve human life."

Dr. Lokesh Narayanan

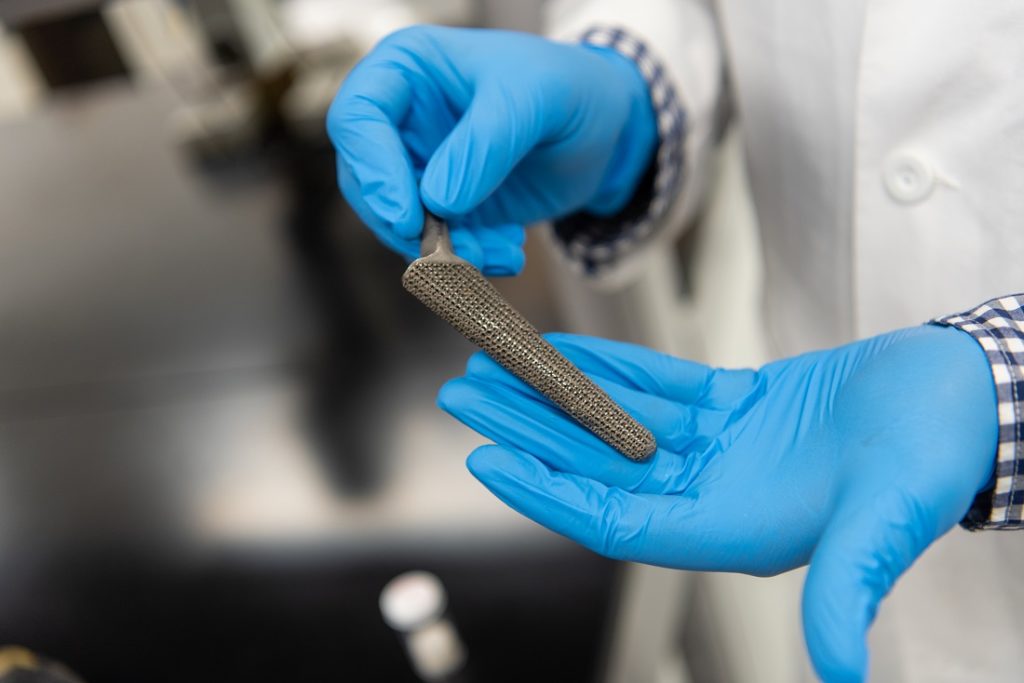

Scientific advancements like the Vacanti mouse have inspired researchers like Dr. Lokesh Narayanan, assistant professor of industrial and manufacturing engineering at North Dakota State University. Lokesh envisions a world in which patients with an injury or illness can receive a customized organ grown from their own unique cells. As an example, he points to a hypothetical patient with a torn ACL whose avascular tissues, when damaged, are unable to repair themselves. According to Lokesh, a patient’s options for healing are limited and not ideal — those who opt for a corrective surgery or plastic implant rarely regain full functionality, he said, and those who require a transplant may wait for months, or even years, until one becomes available.

“So, what if we made tissues with your own cells, custom to your own tissue geometry?” Lokesh asked. “That’s what regenerative medicine is all about.”

Lokesh’s process utilizes human cells collected from a small tissue biopsy and a special 3D printer, called a bioprinter, that creates a biodegradable scaffold to direct the shape of cell growth. A significant portion of his research is funded by the Vettel Family Faculty Fellowship, established by Matt ’90 and Jenna Vettel to support a faculty member in the Department of Industrial and Manufacturing Engineering.

Before he received the fellowship, Lokesh found himself in a difficult position — he wanted to apply for grants to secure funding for his research, but in order for his grants to be successful, he needed to show pilot data.

“To do pilot experiments, you need money,” Lokesh said, “and without that money, you can’t be successful. Now I am capable of doing some pilot experiments and showing data that can support the grants I’m writing, so this fellowship was a must for my research.”

Despite the significant amount of time it takes to write grants (about six months), Lokesh continues to apply because his research is quite expensive. The 3D bioprinter used to print 3D tissue models cost $130,000 and to run his experiment just once costs roughly $7,000. His fellowship funding has covered a significant portion of those costs.

“The challenge here is any research involving living cells is really expensive,” Lokesh said, “so the more money we have, the better quality the research will be.”

The price of his research is one reason he says his faculty fellowship is so vital. But Lokesh also sees it as a growing investment that provides remarkable opportunities for students and the greater NDSU community to improve the quality of human life.

“This fellowship is like a seed — it starts everything,” he said. “The money is going into labs, into equipment, into students, so it’s going to come back to the university. It’s going to increase the reputation of the university, and it’s going to improve the college infrastructure as well. It’s a seed that flourishes into a bigger investment.”

In addition to his fellowship research, Lokesh received a grant that has allowed him to research how moisture affects the 3D printing process with NDSU graduate student and Ph.D. candidate Raihan Quader.

“Donor funding is really important because it actually broadens the exploration area,” Raihan said. “When a project is funded, the department, faculty, and students have the capability to think broadly.”

In the first year of his fellowship, Lokesh generated pilot data and prepared for more student research assistants to join his team. Sri Teja Garapati, an M.S. mechanical engineering student, is working on building a biosensor platform, and Zaidur Rahman, a B.S industrial engineering student, is working on data collection and analysis. Caleb Wing, a B.S. mechanical engineering student, and Sydney Von Arb, a B.S. manufacturing engineering student, joined his team this fall. Through his research, Lokesh has also connected with Sanford doctors with whom he’s currently collaborating on medical modeling.

“The joy, to me, is invention,” Lokesh said. “I know it’s a bit outlandish, but I want to improve human life. If I can invent something that is going to be used by millions and save their lives or improve their quality of life, if I can contribute in any way, it makes me happy.”

Share This Story

Related Stories

Glad You’re Here

NDSU students bring companionship and events to residents in memory care at Fargo’s Touchmark retirement community.

Read More